Vehicle standards and specifications for cars including brakes, engine and exhaust modifications, fuel systems, and wheels and tyres.

Blow off valves

Fitting an aftermarket blow off valve can affect the vehicle's compliance with the exhaust emission requirements specified in the Australian Design Rules, and is therefore not acceptable.

External wastegates on turbocharged engines are not permitted.

Bonnet pins and mascots

The use of bonnet pins that protrude through the bonnet is not acceptable.

Bonnet pins that were original equipment from the manufacturer may be acceptable. Bonnet securing devices that are flush with the contours of the bonnet may be used.

Mascots are acceptable if they were provided as original equipment by the manufacturer for a particular make and model of vehicle.

For more information read MR1457 (685.6 KB PDF)

Bonnet scoops

Fitting a bonnet scoop (forward or rearward facing) to a motor vehicle is only acceptable provided that it is designed, built and fitted in a way that minimises the likelihood of injury to a person accidentally making contact with the vehicle.

For more information refer to Bonnet scoops.

Brakes

It is recommended that braking modifications are carried out using production components that themselves do not require modification.

Requirements for upgrading brakes

When brakes are upgraded using components or systems which were not standard options for the vehicle, a Statement of Requirements or a report from a light vehicle engineering signatory may be necessary.

When the brake system of an early model vehicle is modified, it is recommended that a dual or split circuit brake system be fitted.

If brakes are upgraded - eg front brakes changed from drum to disc, it is essential that:

- the correct master cylinder is fitted

- the brake master cylinder has adequate brake fluid in the reservoir (disc brake systems usually require a larger reservoir)

- front to rear brake balance is compatible and does not result in excessive wheel lockup of one axle during braking

- all components of the braking system are compatible and are unmodified

- the installation is in accordance with the manufacturer's specifications

- all brake tubing and flexible brake hoses must conform to Australian Design Rules.

Alterations to brakes

Brakes must not be altered in any way that would reduce braking efficiency. This includes fitting smaller drums or discs and machining drums or discs beyond the limits set by the component manufacturer.

All brake components shall clear other vehicle components such as wheels, suspension and steering components.

Brake components and brake lines must be mounted in areas where they are not likely to be struck by objects thrown up from the road. They also must be protected from excessive heat and abrasion. The use of copper tubing for hydraulic brake pipes is not allowed. Joining hydraulic brake pipes by brazing, silver soldering, etc is not allowed.

Brakes on light trailers

For information on the requirements for brakes on light trailers see Light vehicle towing and trailer regulations .

Bull bars

On vehicles manufactured on or after 1 July 2013 with a gross vehicle mass (GVM) less than 3.5 tonnes bull bars must conform to the shape of the vehicle.

Over time, this will eliminate aggressive upright or forward-facing bull bars being fitted in South Australia.

Bull bars must be designed and fitted so that the safety of the vehicle is not affected and not be of danger to other road users including pedestrians.

Bull bars must be fitted correctly and be free of sharp protrusions. They must not obscure the driver's view or any vehicle lights including indicators.

Fitting fishing rod holders to the front of a bull bar is not acceptable.

Requirements

All bull bars fitted to vehicles manufactured on or after 1 July 2013 with a GVM of not more than 3.5 tonnes, must comply with the design and installation requirements of Australian Standard AS4876.1-2002 'Motor Vehicle Frontal Protection Systems Part 1- Road User Protection' (except clause 3.2).

This is consistent with the Road Traffic (Light Vehicle Standards) Rules 2018 made under the Road Traffic Act 1961.

In summary

- The profile of the bull bar should follow that of the vehicle in plan, side and front view, and not extend excessively beyond the side profile of the vehicle.

- The bull bar must be designed and fitted so that the safety of the vehicle is not adversely affected.

- It must be firmly and securely mounted and supported, and must not constitute a danger to other road users.

- The bull bar and any fittings, hooks or attachments must not have any sharp edges, corners or protrusions. All exposed sections of the bull bar and fittings must be radiused and deburred.

- The bull bar, together with its mountings and any winch or other equipment and fittings, must be taken into account for vehicle dimensions and shall not increase the overall width of the vehicle.

Airbag and additional fittings requirements

Vehicles fitted with an airbag or manufactured to comply with Australian Design Rules (ADR) 69 or ADR 73 on Occupant Protection, can only be fitted with a bull bar that has been certified by the vehicle manufacturer as suitable for that vehicle, or has been demonstrated by the bull bar manufacturer to not adversely affect the vehicle's compliance with ADR 69 or ADR 73 or interfere with any critical airbag timing mechanism.

Additional fittings such as driving lamp brackets, fishing rod holders or aerial mounting brackets must not protrude above the top or forward of the bull bar.

- Australian Design Rule (ADR) 69 - Full Frontal Impact Occupant Protection 2006

- Australian Design Rule (ADR) 73 - Offset Frontal Impact Occupant Protection 2005

Failure to comply

Bull bars that do not meet Australian Standard AS 4876.1 - 2002 (clauses 1, 2, 3.1 excluding clause 3.2) that are fitted to vehicles manufactured on or after 1 July 2013 with a GVM of not more than 3.5 tonnes may breach a vehicle standards requirement and contravene sections 117 and 118 of the Road Traffic Act 1961.

The vehicle's driver or operator may be summonsed to Court and face penalties or be issued with an expiation fee.

Defect notices for deficiencies caused by a breach of a vehicle standards requirement may be issued for such vehicles under section 145 of the Road Traffic Act 1961.

Light vehicle front protection systems - safety considerations

Colour change

Approval is not required to change the colour of the vehicle.

To notify of a colour change, complete an MR7 Application to alter vehicle or trailer detail (185.6 KB PDF) and submit it to any Service SA centre.

Chassis and body length

Lengthening or shortening a vehicle body is acceptable provided an engineer's report prepared by a light vehicle engineering signatory is presented, certifying that the modified vehicle:

- continues to comply with all applicable Australian Design Rules

- meets the requirements of Brake system test procedure

- meets the requirements of Lane change manoeuvre test procedures

- meets the requirements of Torsional rigidity and beaming stiffness test procedures.

You will need to submit an Application to modify a light motor vehicle for any chassis modification and a statement of requirements will be issued prior to the roadworthy inspection.

Convertibles

The upper body structure or roof of a passenger car contributes significantly to the total strength of the body of a monocoque construction vehicle and its removal can seriously affect the structural integrity of the original design of the vehicle.

There are no specific regulations under the Road Traffic Act 1961 that makes it an offence to remove the roof or upper body structure of a motor vehicle. However, in the case of passenger cars and passenger car derivatives manufactured on or after 1 January 1969, the removal of a vehicle roof may interfere with the Australian Design Rule 5a, ADR 5b or ADR 5/00, relating to the upper seat belt anchorages.

Consequently, modifications to passenger cars and derivatives manufactured on or after 1 January 1969 will only be accepted if an engineering report prepared by a Chartered Professional Engineer is supplied.

The report must demonstrate that the modified vehicle continues to comply with all applicable Australian Design Rules, and that the vehicle meets with Torsional rigidity and beaming stiffness test procedures.

In the case of passenger cars and derivatives manufactured prior to 1 January 1969, no approval or inspection of the modified vehicle is required. However, it is recommended that a Chartered Professional Engineer is engaged to ensure that the integrity of the vehicle has not been compromised.

Engine and exhaust modifications

An alternative engine may be fitted to replace one that is no longer serviceable or to achieve an increase in capacity, power and torque.

If the engine in your vehicle has been changed with no modification and is an available option or standard specification for your vehicle make, model and year, complete MR7 Application to Alter vehicle or trailer details (185.6 KB PDF) form and submit it to Service SA for approval.

If approved, you will be notified of the change.

Engine changes, statement of requirements

Before installing an engine of greater capacity than the one originally supplied, a statement of requirements must be obtained.

When assessing an application the following factors will be considered:

- weight

- power and torque output in relation to braking

- strength of the vehicle

- effect on steering and suspension components

- the effect on vehicle handling.

A Statement of Requirements can be obtained by submitting an Application to modify a light motor vehicle form to Vehicle Standards.

Certificate of exemption

After the modified vehicle has passed a roadworthy inspection a certificate of exemption will be issued to the registered owner.

This certificate of exemption must be kept in the vehicle and produced upon request by a police officer or authorised inspector.

Emission requirements for passenger vehicles operating on petrol

Vehicles manufactured on or after 1 January 1972

Vehicles manufactured on or after 1 January 1972 must comply with Australian Design Rule (ADR) 26, including:

- Vehicles must be fitted with an operational positive crankcase ventilation valve (PCV).

- The exhaust system must not emit more than 4.5% carbon monoxide at engine idle speed.

Vehicles manufactured on or after 1 July 1976 to 1 January 1986

Vehicles manufactured on or after 1 July 1976 to 1 January 1986 must comply with either ADR27A ADR27B or ADR27C, including:

- A carbon canister must be fitted, operational and connected to the fuel tank and induction system.

- The vehicle must also be fitted with sealed engine rocker cover(s), regardless of the engine fitted, vented through the engine's induction system.

- Vehicles must not emit more than 4.5% carbon monoxide and 250 parts per million of hydrocarbons at engine idle speed.

- Per ADR 27A, vehicles must not emit more than 2.5% carbon monoxide and 250 parts per million of hydrocarbons at engine idle speed.

Vehicles manufactured on or after 1 January 1986

All vehicles manufactured on or after 1 January 1986 must comply with ADR 37, including:

- This category of the vehicle may only be fitted with an engine complying with ADR 37 or later ie an engine designed to operate only on unleaded fuel), which incorporates all associated emission control components.

- Fitting an engine other than an original or optional engine requires approval from the Department for Infrastructure and Transport.

- No alterations to the engine's camshaft, inlet manifold, carburettor/fuel injectors, engine control unit or catalytic converter are permitted.

- Airflow meters must not be disconnected.

- Modified or aftermarket plenum chambers or throttle bodies are not permitted.

- Extra or larger fuel injectors or variable fuel pressure regulators are not permitted.

- If the vehicle was originally fitted with a catalytic converter by the manufacturer, the vehicle must continue to operate with one.

Passenger car derivatives - panel vans and utilities under 4.5 tonne GVM

The requirements for passenger car derivatives manufactured on or after 1 July 1976 are identical to those for passenger cars.

For vehicles manufactured prior to this date, there are no requirements except for positive crankcase ventilation (PCV).

Exhaust systems and noise

Modifications to exhaust systems are permitted if they do not conflict with the requirements of any other rules or regulations.

Vehicles also must meet the following requirements:

- Vehicles may be fitted with extractors provided that any emission control devices which were originally fitted to the original manufacturer's exhaust system, including catalytic converters, are re-connected and operational.

- The extractors must not foul any part of the steering, suspension, braking or fuel systems.

- Catalytic converters and exhaust sensors that have been replaced are to be positioned in the same exhaust flow location as in the original system.

- The exhaust outlet exit must be behind the last door or window opening on the side or rear of the vehicle.

- The exhaust outlet must be as close as possible to the outer edge of the vehicle, but not outside or underneath the vehicle.

- If the exhaust system is not underneath the vehicle and can come into contact with people, it must be shielded.

- The exhaust outlet must extend at least 40 mm beyond the furthermost outboard or rearmost joint of the floor pan that is not continuously welded or permanently sealed and which could permit direct access of exhaust gases to the passenger compartment, but not beyond the perimeter of the vehicle when viewed in plan.

- The side exhaust outlet must discharge downwards at an angle between 15 degrees and 45 degrees from horizontal.

- The exhaust outlet, if to the rear of the vehicle must discharge at not more than 10 degrees above or 45 degrees below the horizontal.

- The vehicle must have 100 mm ground clearance.

Extractors and aftermarket exhaust systems may be fitted provided that the sound levels specified in the Road Traffic (Light Vehicle Standards) Rules 2018 are not exceeded.

For passenger cars, passenger car derivatives and panel vans manufactured:

- before 1 January 1983, the stationary noise level when tested must not exceed 96 dB(A)

- on or after 1 January 1983, the stationary noise level when tested must not exceed 90 dB(A).

Engine management systems

In modern vehicles, the engine management system (computer) is an integral part of the emission control system.

Re-calibrating the engine management system either by changing the chip, re-programming, or replacing the unit with an aftermarket computer may result in non-compliance with the emission control Australian Design Rules (ADRs) applicable to the vehicle.

Testing a production vehicle for compliance with ADR emission control standards is a lengthy and expensive process and can only be undertaken with testing equipment acceptable to the Department for Infrastructure and Transport (DIT).

DIT may consider the fitting of an aftermarket engine management system where an engine upgrade takes place, however, this will be on the condition that an IM240 emission test is performed.

An Application to modify a light motor vehicle form must be submitted to Vehicle Standards.

Fibreglass or carbon fibre panels

The use of custom made fibreglass or carbon fibre body panels is acceptable provided that the structural integrity of the body is not adversely affected and the vehicle continues to comply with all relevant Australian Design Rules.

When fitting a carbon fibre bonnet, it must be manufactured in a way that it:

- is of equal strength to the original

- retains the under-bonnet ribbing/structure

- is mounted using the original bonnet catch and hinges.

Fuel systems

Fuel lines

Fuel lines must meet the following requirements:

- The material used for fuel lines must be a suitable grade for use with automotive fuels.

- Fuel lines must be securely fastened and must not leak.

- Push-on-type hose connections must be fitted with hose clamps or clips.

- Fuel lines must be clear of the exhaust system and any turbocharger.

- Where fuel lines pass through panels, bulkheads or the chassis they must be adequately supported and protected from chafing or damage.

- When fitted under a vehicle, fuel lines must be protected from road debris and damage either by chassis or body components by shielding.

Fuel filters and pumps

Additional fuel filters and alternative or replacement fuel pumps may be fitted provided that:

- the installation is in accordance with good engineering practice

- no pump, fuel line or filter is located within the occupant compartment or boot

- all components are unmodified

- the fuel pump stops when the ignition is in the off position

- the alternative/replacement fuel filter or the fuel pump is secured and shielded against heat and damage

- and that there are no leaks.

LP gas or petrol and LP gas

Vehicles that are equipped to operate on dual fuel - eg the vehicle can operate on either petrol or liquefied petroleum gas (LPG) - must retain all original emission control equipment, except for the air cleaner, carburettor, heated inlet air, and associated equipment. These may require modifications to facilitate the installation of the LPG intake system.

The vehicle must also comply with petrol-related regulations. Any emission control systems that were fitted eg catalytic converters and oxygen sensors - must remain operational.

Conversion of a vehicle to operate on LPG must be performed to AS/NZS 1425 - LP Gas Fuel Systems for Vehicle Engines.

Only a licensed person is allowed to install or repair LPG equipment. A current identification plate must be fitted to certify that the LPG system meets the requirements of AS/NZS 1425.

Dedicated (single) fuel

Vehicles that are not required to comply with Australian Design Rule (ADR) 37 (pre 1 February 1986), and which are running solely on LPG, need not be fitted with emission control equipment, provided that the following requirements are met:

- The vehicle exhaust emits less than 4.5% carbon monoxide at recommended engine idle speed.

- The petrol pump, fuel tank, carburettor, fuel supply lines, and any other associated equipment related to the petrol fuel system are removed from the vehicle.

- Vehicles built to comply with ADR 37 and later, must retain all emission control equipment including the catalytic converter.

- From 13 December 1993, vehicles originally designed to operate with a closed-loop engine management system must have an LPG closed-loop management system installed which results in exhaust emission levels for LPG operation that are not inferior to the levels produced by the original vehicle prior to LP gas fitting.

Replacement fuel tanks

Fitting replacement or additional fuel (petrol) tanks to vehicles manufactured prior July 1976 does not contravene the requirements of Road Traffic Act and Regulations, provided that sufficient ground clearance is retained and they are fitted outside the passenger compartment.

For vehicles manufactured on or after 1st July 1976 the ADR requirements for evaporative emission controls must be met, including:

- All fittings and devices fitted to the fuel tank by the vehicle manufacturer must be retained or duplicated and operate correctly.

- The fuel tank and filler shall be arranged so that any overflow or leakage of fuel cannot accumulate or contact the exhaust or electrical systems.

- Fuel tanks fitted to the vehicle are normally required to be filled and vented externally.

- If a filler inlet is located inside a vehicle, it must not be inside the passenger compartment and the inlet must be separately sealed from the rest of the vehicle to ensure fumes or spilled fuel cannot enter the passenger cabin.

- There must be no lights or electrical wiring in the area where the fuel filler is located.

- The minimum ground clearance of 100mm must be retained.

Hazardous projections

An object fitted to a vehicle must be designed, built and fitted to the vehicle in a way that minimises the likelihood of injury to a person making contact with the vehicle.

However, if the vehicle was designed before 1965 and such object was part of the design of the vehicle this may be permissible.

All equipment inside the vehicle such as fire extinguishers, GPS navigation or additional gauges should be securely fastened.

It is recommended that cargo anchorage systems should be capable of withstanding a force equal to twenty times the mass of the equipment.

Cargo barrier protection screens are available for many station wagon and light commercial vehicles and are highly recommended.

No vehicle may be equipped with:

- any object or fitting not technically essential to the vehicle eg fishing rod holders.

- any object or fitting technically essential to such vehicle unless its design, construction and conditions and the manner in which it is affixed to the vehicle reduces to a minimum the risk of bodily injury to any person

- any object or fitting which, because it is pointed or has a sharp edge, is likely to increase the risk of bodily injury to any person

- any bumper bar, the end of which is not turned towards the body of the vehicle to a sufficient extent to avoid any risk of hooking or grazing.

For more information read Hazardous projections.

Intercoolers

Intercoolers can be fitted to vehicles providing:

- there are no sharp projections ahead of the front bumper that may increase the risk of injury to other road users, including pedestrians

- the intercooler is fitted and secured in a manner in accordance with normal automotive engineering practices, and the structural integrity of the vehicle has not been affected

- adequate provision is made for a complying number plate to be fitted in an approved position.

Lighting and instrumentation

Lighting

Additional lighting systems are to be fitted strictly in accordance with South Australian legislation and must be marked to be compliant to Australian Design Rules.

You may fit up to a maximum of four additional lights, in pairs, provided the lights show a white beam only.

Lights fitted must not affect the driver's view and must be mounted symmetrically. Additional driving lights must extinguish automatically when low beam is selected.

All headlamps must be mounted at the front of the vehicle.

Front fog lights

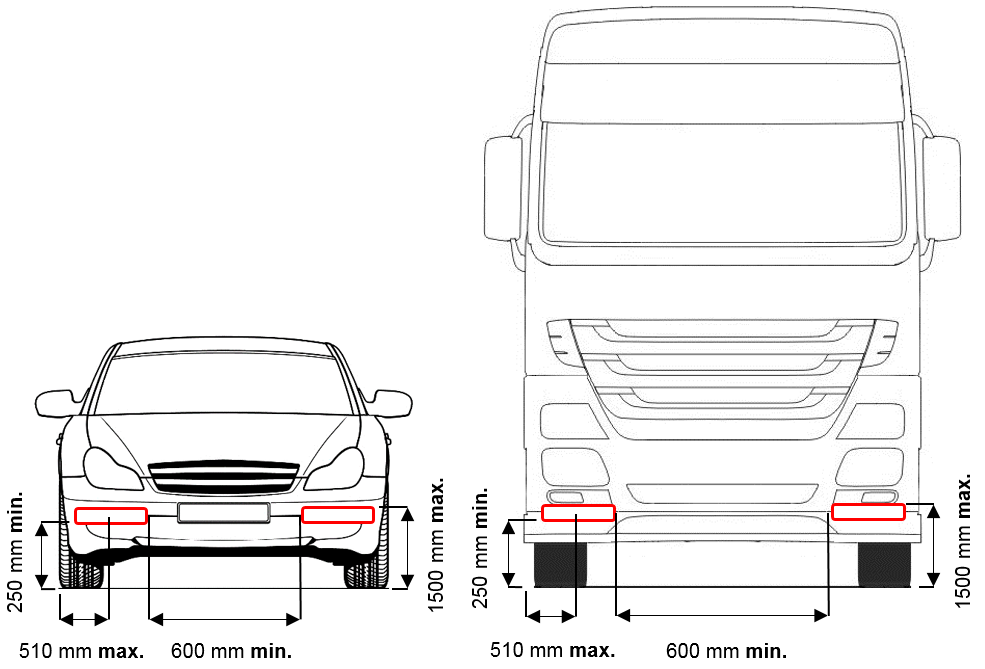

A pair of fog lights, showing a beam of white or yellow light may be fitted to the front of a motor vehicle with the centres no higher than the top of the dipped beam headlight.

The lights must be mounted symmetrically not less than 600mm apart.

Fog lights must be capable of being switched on and off independently of any headlights and must only be able to be switched on when the parking lights are on.

Fog lights can only be used in fog or conditions with reduced visibility.

Coloured lights

Coloured under-car neons lighting systems are not approved. A vehicle can not show coloured light other than what is specified in the Road Traffic (Light Vehicle Standards) Rules 2018, and the Australian Design Rules.

Red and blue lights are only allowed on emergency vehicles - eg police, fire and ambulance.

Red lights and reflectors must only face rearward of the vehicle.

White lights and reflectors must face forwards.

Yellow/amber lights are permitted for indicators, fog lights and for side clearance lights on large vehicles and buses. With the exception of indicators, amber flashing lights are not permitted on any vehicle, other than special vehicles used in hazardous situations and emergency vehicles.

Replacement headlight bulbs must display compliant Australian Design Rules or equivalent markings.

Daytime running lamps

Daytime running lights are bright white forward-facing lights that improve the visibility of a vehicle in the daytime.

A pair of daytime running lamps may be fitted to a motor vehicle, symmetrically about the centreline of the vehicle. The lights must be wired so they are not illuminated while the vehicle's main headlights are on.

They also must conform to location and performance requirements outlined in the Australian Design Rules 13/00 and 76/00 respectively. Daytime running lamps should not be fitted to the roof, bonnet or side rear vision mirrors.

LED Light Bars and additional driving lights

LED Light Bars and additional headlights may be fitted, provided that they meet the following requirements:

- The light or lights must be installed to be forward facing and in a position that does not obscure the driver's view of the road ahead.

- The lights should, as far as is possible, be installed symmetrically in pairs of between 2 or 4 lights.

- If the lights are not fitted as pairs, they must be fitted symmetrically about the centre line of the vehicle.

- The lights may be fitted to the roof of the vehicle.

- The light or lights must not be fitted or be used in any way that is likely to dazzle another road user and must be installed in a way that the light produced does not cause the driver of the vehicle discomfort either directly or by reflection.

- The light/s must only come on when the main-beam (high beam) headlights are used, and must automatically turn off when the main-beam headlights are turned off.

- The driving lights may be fitted with an isolator switch to allow high beam to be switched on without the driving lights also being switched on.

For more information see Driving lights.

HID (high-intensity discharge) headlamps

HID light bulbs, also known as xenon lights, produce light by creating an electrical arc across two electrodes, resulting in a much brighter white/blue light than normal halogen light bulbs.

Fitting HID headlamps is permissible providing that they are fitted with automatic headlamp levelling devices and headlamp cleaners. They must also conform to any requirements in set in Australian Design Rule 13.

Instrument panels

Manufacturers are required by Australian Design Rule 21 to provide crash padding for the instrument panel in vehicles manufactured on or after 1 January 1973.

If any additional equipment such as gauges, switches and audio systems are installed they must not protrude beyond the dash padding or be mounted on top of or below the dash where they are likely to cause reduced vision or increase injury in a collision.

Visual display screens

DVD screens, television receivers and visual display screens may be installed in a motor vehicle.

The screen must not be visible to the driver from the normal driving position, except if the screen turns off when the vehicle is moving, or it is a driver's aid - eg GPS navigation or reversing camera.

A screen must not obscure the driver's view of the road or impede the movement of anyone in the vehicle. It must be designed and installed so that it does not increase the risk of bodily injury to any person.

Mudguards and mudflaps

Mudguards must be fitted to all road wheels and must cover the full width of the tyre when viewed from directly above.

They must prevent direct contact with the upper half of the wheel in forward collisions and be designed to reduce the dangers to road users from contact with moving wheels.

They must deflect downwards any stones, mud, water or other material thrown upwards by the rotation of the wheels.

For vehicles manufactured on or after 1 July 1988, specific requirements relating to the design and construction are contained in Australian Design Rule 42.

The wheel guard including the mudflap (if fitted) must be no higher than 230 mm from the ground and for off-road vehicles no higher than 300 mm from the ground. For more information on this requirement see the Road Traffic (Light Vehicle Standards) Rules 2018.

Oil 'catch cans'

An oil catch may be fitted provided it is vented back into the vehicle's crankcase so that oil or fumes do not escape to the atmosphere.

Venting any engine emissions to the atmosphere is not permitted.

Roll cages

Due to the increased risk of occupant injury in vehicle accidents, fitting full roll cages is not permitted. However, fitting a half roll cage rearward of the driver may be acceptable providing that:

- no part of the roll cage can be contacted by vehicle occupants when positioned in their normal seating position

- the roll cage is at least 150 millimetres behind the front seat occupants when the front seats are located in the most rearward adjusted position

- all rear seats and seat belt assemblies fitted in the rear compartment are removed

- the operation and effectiveness of the front seat belt assemblies is not affected in any way by the roll cage

- no person travels in the rear of the vehicle at any time

- the vehicle has a seating inspection carried out by the Department for Infrastructure and Transport.

Seats and seat belts

Seats

Additional or replacement seats must be installed in accordance with the current issue of Vehicle Standards Bulletin 5 - Manufacture and installation of additional seats.

The addition or removal of seats requires a seating inspection by the Department for Infrastructure and Transport (DIT).

The vehicle will then be fitted with a seating label to reflect the new seating arrangement.

The removal of seats or seatbelts to achieve a reduction in seating capacity must not interfere with the vehicle's supplementary restraint system (SRS) - eg removing a front seat and seatbelt with pre-tensioners may disarm the entire vehicle's SRS and therefore would not be approved.

Temporary removal of seats

Many 4WD owners who use their vehicles for holidays and camping sometimes would like to use the rear space of their 4WDs for camping equipment or for extra luggage room. Therefore it would be useful to temporarily remove the rear most seats in the vehicle.

If the removal of seats is temporary DIT does not need to be advised, and no seating inspection is required.

If the seat cannot be returned to its original position because of the permanent removal of an anchorage point, then a seating inspection is required and Service SA will need to be notified of the change.

The temporary removal of seats in vehicles in particular to 4WD's with rear seats for seven or eight passengers, is permissible providing that:

- when removing rear seats that no tools or only simple tools are required

- no seat, seat belt or child restraint anchorages are removed or modified and no modification has been made to the seating capacity

- there are no structural modifications involved and there is no change in the vehicle's registration category.

Seat belts

Under the Road Traffic Act and Regulations seat belts are required in the driver's and front outboard seating positions from 1 July 1967.

Seat belts for all front seating positions became mandatory from 1 January 1969 and for all seating positions from 1 January 1971.

The level of safety provided by seat belts must not be reduced. Seat belts must not be replaced by belts of a lesser design rule standard.

A person must not sell a seatbelt or part of a seatbelt for use in a motor vehicle that has previously been installed in another vehicle.

There is no objection to seat belts of a higher standard being fitted, however it is recommended you contact DIT for advice to ensure that the belts are of the correct type and can be correctly fitted.

Seat belt anchor points are carefully chosen and tested by the vehicle manufacturer. Therefore it is not permitted to alter the location or the strength of the seat belt anchorage points without advice from a Chartered Professional Engineer.

Fitting harness belts to passenger vehicles manufactured on or after 1 January 1969, but prior to 1 January 1975, will only be considered on presentation of an engineering report prepared by a Chartered Professional Engineer that demonstrates continued compliance with Australian Design Rule 5A and that there is no rear seating position.

Australian Design Rule 5A - Seat Belt Anchorages

Fitting harness seat belts to passenger vehicles manufactured to comply with Australian Design Rule 4B manufactured on or after 1 January 1975, is not permitted as the Australian Design Rule requires the inclusion of a dual locking retractor system.

Australian Design Rule 4B - Seat Belts

Light vehicle engineering signatory

Spoilers and wheel guard flares

Cosmetic body modifications such as wheel guards, side skirts and front or rear spoilers are permitted without approval provided that they are fitted with regard to the safety of other road users.

Front spoilers must meet ground clearance requirements of 100 mm. It is recommended that the airflow for the brake cooling is not adversely affected.

Rear spoilers must be within the original body profile of the vehicle.

There must not be any sharp edges that could increase the severity of injuries to pedestrians and other road users. See also Hazardous projections.

The fitting of a rear spoiler that incorporates a brake light requires any originally fitted equipment eye-level brake light to be disconnected.

Steering modification

Steering conversions

All vehicles converted from left-hand drive to right-hand drive must be converted in accordance with the Code of Practice for Steering Conversions for Left Hand Drives.

An engineering report prepared by a light vehicle engineering signatory must be submitted specifying that the requirements of VSB Number 4 have been met.

For all steering conversions, an application to modify should be sent to Vehicle Standards. You will be sent a Statement of Requirements to complete.

Application to modify a light motor vehicle

The statement of requirements is required by Department for Infrastructure and Transport before a vehicle can be booked for inspection.

Vehicles fitted with welded steering components must comply with the requirements set out in VSB Number 4. Welded steering components are not acceptable unless certified by a chartered professional engineer.

Modified steering components

Welding, heating or chroming axles, stub axles, steering arms and steering knuckle supports are not acceptable unless an engineering report prepared by a Chartered Professional Engineer, is presented, which demonstrates that the modifications are at least as strong as the original and contain no latent defects.

Light vehicle engineering signatory

Steering wheels

Steering wheels are designed to minimise injury to the driver during a vehicle accident.

When replacing a steering wheel make sure that the new steering wheel complies with Australian Design Rule (ADR) requirements.

Replacement steering wheels must not be less than 330 mm in diameter. If the original steering wheel was designed with a recessed or padded hub, the replacement wheel must be of a similar design.

A non-standard aftermarket steering wheel may be fitted to passenger cars and derivatives manufactured prior to 1971. When selecting a replacement steering wheel ensure that it is firmly padded and is constructed so that it will bend on impact without splintering or cracking, and that no parts of the wheel are loose or cracked.

Passenger vehicles built after 1970 are required to comply with ADR 10. The replacement steering wheel must have the appropriate markings indicating that it complies with ADR 10. There are a number of steering wheels certified to ADR 10, so before purchasing an aftermarket steering wheel contact Vehicle Standards to ensure that it is acceptable.

Passenger vehicles manufactured after June 1995, which are required to comply with ADR 69 (full frontal impact occupant protection), may only be fitted with steering wheels certified by the vehicle manufacturer as suitable for that vehicle.

For example, if your vehicle has an airbag steering wheel as standard, the replacement must be the same. Fitting an aftermarket steering wheel to a vehicle that has an airbag in the original steering wheel is not acceptable.

Suspension modifications

Lowering vehicle height

Acceptable 'eyebrow heights' (the measurement from the centre of the wheel vertically upward to the edge of the mudguard) or 'bump rubber clearance heights' (the clearance between the bump rubber and corresponding contact point) for most passenger vehicles can be found here - Passenger vehicle (cars and 4WDs ) wheel track list for 1970 and later vehicles.

Other requirements for lowering a vehicle include:

- either front or rear, the suspension travel must not be reduced by more than one-third of that specified by the vehicle manufacturer

- the vehicle must also retain 100 mm ground clearance which is measured between any part of the vehicle and the ground

- all measurements must be carried out with the vehicle on level ground in its normal operating but unladen state

- coil springs must not be shortened by cutting, and no suspension component is to be subjected to heating

- lowering blocks may be used on leaf spring suspensions provided they are manufactured from steel, aluminium, or metal and to be positively located to the axle spigot hole and the spring centre bolt. The axle mounting 'U' bolts must not be below the lower rim height.

Replacement coil springs must have:

- clearance between the coils when the suspension is at full bump

- the same or greater load capacity as the original springs

- sufficient force between the spring and its seat for it to remain correctly seated when the suspension is at full droop

- the same end shape as the original springs.

Lowering blocks may be used on leaf spring suspensions provided they are manufactured from steel, aluminium, or a metal of equivalent strength and are positively located to the axle spigot hole and the spring centre bolt. It should be noted that the axle mounting 'U' bolts are not permitted to be below the lower rim height.

Rubber or other resilient bump stops must be provided where the suspension or axle are likely to bottom out or result in the spring being coil bound (ie no clearance between coils at full bump).

When the ride height of a vehicle is lowered, the vehicle must still comply with other legal requirements - eg lowering the vehicle will affect the height of the vehicle's lights and reflectors and these have to remain within specific legal boundaries ie headlamps must be at least 500 mm above the ground, measured from the centre of the light.

Raising vehicle height

Vehicle ride height can be increased by a total of 50 mm without a roadworthiness inspection.

The ride height can be raised by one of three methods or a combination of them up to a maximum of 50mm.

- Suspension lift - fitting longer travel springs

- Body lift raising the body of the chassis

- Tyres fitting of larger diameter tyres

A total lift of more than 50 mm requires prior approval in the form of a statement of requirements and a report from a Light Vehicle Engineering Signatory (LVES). A roadworthiness inspection will also be required.

Raising a vehicle is not generally recommended due to cornering and braking instability that may result. Often vehicles are raised because the owner wants to fit large wheels and tyres that would otherwise contact the mudguards. In these cases, the wheels and tyres may be unacceptable.

When raising the height of your vehicle's suspension, you must ensure the original amount of rebound travel is maintained. The rebound must be limited by the same method as the original manufacturer, ie limit straps or shock absorber full extension.

The body of a vehicle can be raised by up to 50 mm by fitting spacer blocks between the vehicle chassis and body at their mounting points. The blocks must be manufactured from steel, aluminium, or a metal of equivalent strength.

In some cases the steering shaft may have to be extended and longer brake hoses fitted. If the original steering components are altered or replaced, you will need to:

- submit an Application to modify a light motor vehicle form to Vehicle Standards

Application to modify a light motor vehicle

- have a roadworthiness inspection

- a report from an LVES may also be required.

Vehicle ride height cannot be raised by:

- wedges or blocks located between the coils.

- relocating a leaf spring on the opposite of an axle to that of the vehicle manufacturer

- spacer blocks mounted above or below the coils spring or mounted between the top of the suspension strut and vehicle body.

- extended or adjustable shackle plates on leaf springs.

Fitting tyres and rims with a larger diameter to those listed on the vehicle's tyre placard may also affect vehicle ride height.

It is acceptable to provide that the overall diameter of the alternative rim/tyre combination is not greater than 15 mm over the largest combination or 15 mm smaller than the smallest combination specified on the vehicle's tyre placard.

In four-wheel drive vehicles an increase in overall diameter of up to 50 mm is acceptable.

Auxiliary suspension devices

Auxiliary suspension devices may be fitted. Sway bars may be fitted to your vehicle. Sway bars add roll stiffness at the front which may increase under-steer, and additional roll stiffness at the rear may create an increase in over-steer that could lead to unpredictable handling.

Track rods/traction bars may be fitted to control rear spring 'wind-up' provided that they meet the minimum ground clearance requirements.

Strut braces may be fitted between suspension strut and spring mounting towers.

Adjustable coil-over suspension

Aftermarket adjustable coil-over suspension components are suspension units that incorporate an external thread on the main body and corresponding threaded spring saddle that allows the vehicle's suspension height to be varied.

If fitting aftermarket or coil-over suspension components you must submit an Application to modify a light motor vehicle form and a report from a light vehicle engineering signatory (LVES).

Application to modify a light motor vehicle

The report must specify and include the following points:

- the suspension travel must have at least two-thirds of the amount of suspension travel of the original suspension system fitted buy the manufacturer of the vehicle

- fitment of a rubber bump stop to limit travel to ensure there is clearance

Tilt fronts

'Tilt front' is a term used to describe a type of forward pivoting integral engine bonnet, grille and front mudguard assembly for front engine vehicles.

Examples of production vehicles fitted with this type of engine access are the Jaguar 'E' type and the Chevrolet Corvette.

The fitting of a tilt front is only acceptable if:

- The new body sections are designed and constructed with no dangerous or sharp projections so that in the event of an accident the risk of injury to pedestrians and cyclists is minimised.

- The new body sections do not obstruct the visibility of lamps fitted to the front of the vehicle, particularly the direction turn signal lamps (indicators) or headlamps.

- The new body sections do not obstruct the field of view of the driver.

- The field of view requirements are determined as follows:

- with the driver's seat in the rearmost position, it is possible to see, unobstructed for the full width of the vehicle, a line drawn on the roadway 11 metres ahead of the driver's eye position when looking over the bonnet

- for the purpose of this requirement the driver's eye position shall lie at the bottom of the 95th percentile eye ellipse (reference Australian Design Rule (ADR) 15/01 clause 15.1.5.1)

- alternatively, the driver's eye position can be taken as a point 750 millimetres above and 270 millimetres forward of the junction of the seat cushion and seat squab with the seat in the lowest and rearmost position

- all lights fitted to meet the requirements of Road Traffic (Light Vehicle Standards) Rules 2018 and where applicable Australian Design Rule 6/00 the anchoring, hinge and latching mechanisms are durable and have sufficient strength to secure the hinged section.

The Department for Infrastructure and Transport may request a submission from a Chartered Professional Engineer if doubt exists concerning the strength of components.

In the case of passenger cars and derivatives manufactured on or after 1 January 1969, in addition to the above, an engineering report presented by a Chartered Professional Engineer demonstrating that the vehicle continues to comply with Australian Design Rule requirements, may be required.

Turbocharger boost controllers

Alteration to an engine's turbo boost pressure is not acceptable. This is specified and set by the vehicle manufacturer to ensure compliance with the Australian Design Rules.

Turbo-charging/supercharging petrol engine vehicles

Turbo-charging or supercharging an engine increases the power of the engine and may increase the exhaust emissions, fuel consumption and reduce the service life of the engine.

Passenger cars and passenger car derivatives (car type utilities and panel vans) manufactured prior to 1 July 1976 and fitted with petrol engines can be fitted with a turbocharger or supercharger to the original manufacturer's engine without DIT approval.

For cars manufactured on or after 1 July 1976 the fitting of a turbocharger or supercharger requires one of the following:

- the vehicle is fitted with a Second Manufacturer's plate to demonstrate compliance with all Australian Design Rules

- the vehicle to pass an IM240 emissions test

- the converted vehicle is identical to the production turbo/supercharged vehicle.

In all cases a statement of requirements is required and the vehicle must pass a roadworthiness inspection.

Certification from a professional engineer may also be required. See the list of qualified engineers recognised by DIT - light vehicle engineering signatory

Turbo timers

Turbo timers are not to be fitted to vehicles manufactured on or after 1 January 1972.

Australian Design Rule 25 (Anti-Theft Lock) requires that the normal function of the engine only occurs when the ignition lock is in the engine 'on' position.

Wheel tubs

Fitting wheel tubs ie alterations to the inboard structure of the rear wheel housing, is acceptable provided that:

- the modification does not weaken the vehicle's structure

- there are no modifications to body structural members, chassis members or suspension mounting points and that there are no body modifications undertaken within 200 mm of any seat anchorage or seat belt anchorage.

Alterations may be permitted provided that an engineering report prepared by a Chartered Professional Engineer is submitted demonstrating that the original strength has not been decreased. - wheels or tyres do not foul any part of the vehicle's suspension, brake lines or bodywork for the full range of suspension movement.

Wheels and tyres

Since 1973 all cars are fitted with a tyre placard (usually fitted in the glove box, the engine bay, or on a door pillar). This specifies the wheel and tyre combinations recommended by the vehicle manufacturer. It also specifies load capacity, speed rating and the recommended tyre air pressure.

Replacement wheels

Replacement wheels may be fitted, provided they comply with the following requirements.

- Ensure that the replacement wheels have been designed for the vehicle's hub and have the same bolt or stud spacing as the original and the same centre location method.

- Ensure the offset of the rim is not reduced by more than 13 mm from the original rim.

- The wheel track must not be increased by more than 26 mm beyond the maximum specified by the vehicle manufacturer. Maximum allowable track measurements for individual vehicle models can be obtained from the Department for Infrastructure and Transport.

- Spacers are not permitted between the hub and wheel unless originally fitted by the vehicle manufacturer.

- Rims that have been widened by inserting a spacer band are not permitted.

- Rims must have no more than one circumferential weld.

- Welding must be carried out in accordance with recognised engineering standards, and the rims must comply in all respects with specifications contained in the Tyre and Rim Association of Australia - Standards Manual.

- The wheels must not foul the body, suspension or any part of the vehicle under any operating conditions and must not project beyond the bodywork when the wheels are in the straight-ahead position and viewed from above.

- If the wheels of a vehicle are retained by multiple nuts or set screws, not by splines and a single nut, then the wheel nuts must match the tapered holes in the wheel and the nuts must be engaged for their full depth of thread.

- Wheel rims fitted to passenger cars manufactured after 1 July 1985, which are not original equipment or an original equipment replacement by the vehicle manufacturer, must be indelibly marked with the wheel's nominal diameter, width and offset and with the identification of the manufacturer of the wheel and the standard to which the wheel was manufactured.

- The use of composite wheels (two or three-piece) is permitted if they are manufactured and marked in accordance with the standards described above and fitted to vehicles manufactured on or after 1 July 1985.

- Modifications to disc brake calipers, hubs and suspension and steering components to enable the fitting of replacement wheels are not allowed without a certificate from light vehicle engineering signatory.

Wheel track

The fitting of aftermarket wheels to your vehicle may result in the vehicle's wheel track being altered. If the wheels you fit have a different offset, compared with the original wheels, then the wheel track will change.

The wheel track is the distance measured across an axle from the centre line of the tyre tread to the centre line of the other tyre on the opposite tyre tread.

Passenger vehicle (cars and 4WDs ) wheel track list for 1970 and later vehicles specifies the maximum allowable wheel track for light passenger vehicles.

The wheel track of passenger cars (or derivatives) can be increased by up to 26mm beyond the maximum wheel track measurement specified for that make and model by the vehicle manufacturer.

The wheel track of the following specified class of vehicles must not be increased by more than 50mm beyond the minimum specified by the vehicle manufacturer:

- all four-wheel-drive vehicles of the Australian Design Rule Categories MC and NA have Gross Vehicle Mass (GVM) greater than 2.3 tonnes and have a selectable low and high range transmission;

- all four-wheel-drive vehicles of the Australian Design Rule Categories NB;

- all goods vehicles of the Australian Design Rule Categories NA2 & NB;

- all four-wheel-drive passenger vehicles manufactured before 1 August 1989 have GVM greater than 2.3 tonnes, and with special features for off-road operation;

- two-wheel drive vehicles of the Australian Design Rule Categories NA, NB1 and other vehicles that have equivalent running gear and chassis to the four-wheel-drive variant of that model vehicle of the same categories.

The Track List for 1970 and later 4WD vehicles (MR1675) (1.1 MB PDF) specifies the maximum allowable wheel track.

The tyres must not protrude outside of the vehicle bodywork and the mudguards cover the full width of the tyre and not be higher than 300 millimetres above ground level.

Tyres

The overall diameter of a wheel and tyre fitted to a vehicle must not be more than 50mm (4WDs) or 15 mm (other vehicles) larger than the largest tyre size listed on the tyre placard and not more than 15 mm less than the smallest tyre size listed on the placard on all vehicles.

Specifications for overall tyre diameters are listed in the Tyre and Rim Association of Australia - Standards Manual. Note: if tyres are to be fitted with a diameter outside of this requirement then submit an Application to modify a light motor vehicle form and a report from a light vehicle engineering signatory is required.

Application to modify a light motor vehicle

The following requirements must also be met.

- The tyres fitted must be suitable for the rim. The tyre retailer should have information about matching tyres and rims. Specifications for overall tyre diameters are listed in the Tyre and Rim Association of Australia - Standards Manual.

- The tyres must be free of any apparent defect that could make them unsafe.

- The replacement tyres must have a load capacity not less than the lowest load rating specified on the tyre placard.

- The speed rating of the tyres fitted to vehicles for off-road must be of at least 140 km/h ('N') when the tyre placard requires a higher speed rating than 'N'.

- The speed rating of the tyres fitted to a passenger vehicle must be at least 180 km/h ('S') when the tyre placard requires a higher speed rating than 'S', for all other vehicles a speed rating of at least 120 km/h applies ('L').

- Tyres fitted to an axle of a vehicle must be of the same size and carcass construction.

- Tyres fitted to vehicles manufactured after 1972 must be made of the same carcass construction - eg radial, cross-ply.

- Tyres fitted to passenger cars may not be treated by recutting or re-grooving of the tread unless the tyre is constructed to do so and marked as such.

- Tyres fitted to a vehicle, which do not have tyre wear indicators, must have a tread pattern at least 1.5mm deep on all parts of the tyre that normally come into contact with the road surface. If the tread has worn down to any of the tyre wear indicators, or there is less than 1.5mm of tread depth on the tyre, the tyre is then considered to be unroadworthy.

Window tinting

Surface films reduce light transmission through windscreens and windows. This can significantly reduce a driver's vision, particularly at night and during periods of low visibility.

The windscreen of a motor vehicle must have a luminous transmittance of at least:

- 75% for a motor vehicle built after 1971

- 70% for any other motor vehicle.

The windscreen of a vehicle cannot be fitted with a film that reduces visible light transmittance except for the area above the highest point swept by the windscreen wipers or the upper 10% of the windscreen.

If the windows of a motor vehicle are coated to reduce light transmittance, the following requirements apply:

- visible light transmittance must not be less than 35% when measured through glass and the film together

- reflectance in the visible light range must not exceed 10%.

For more information read Window tinting.

Windscreens and windows

Any replacement glass fitted to a motor vehicle, including an interior partition, must be of appropriate automotive safety glass or other approved material and must comply with the Standards.

Some manufacturers incorporate the windscreen and rear window into the structural design of the vehicle and if improperly secured may reduce the crash worthiness of the vehicle.

Vehicle glazing must comply with the same characteristics as material mentioned in any of the following standards:

- AS208, ECE R43/00, BS AU178, JIS R 3211, AN Z26.1 or NZS 5443.

- The windscreen glass must carry the indelible mark or marks of the relevant standards. These must be visible when the windscreen is fitted in the vehicle, and the marking must identify the type of glass and the relevant standard to which the glass conforms.

- All replacement transparent material must be of a type that will not shatter.

- The windscreen must be free from scratches, cracks or chips.

Related information

Other websites

Legislation

Vehicle Standards reference: see also PDF MR1457.